- Who we are

- Services

- Projects

Ongoing

HECOTEC LLC aims to provide world-class Engineering, Procurement, Construction, Management and Inspection services in the regional and global market.

Ongoing

HECOTEC LLC aims to provide world-class Engineering, Procurement, Construction, Management and Inspection services in the regional and global market. Delivered

HECOTEC LLC aims to provide world-class Engineering, Procurement, Construction, Management and Inspection services in the regional and global market.

Delivered

HECOTEC LLC aims to provide world-class Engineering, Procurement, Construction, Management and Inspection services in the regional and global market. Projects our staff involved

HECOTEC LLC aims to provide world-class Engineering, Procurement, Construction, Management and Inspection services in the regional and global market.

Projects our staff involved

HECOTEC LLC aims to provide world-class Engineering, Procurement, Construction, Management and Inspection services in the regional and global market.

- News

- Contact

- Inspection: Analyzing the current condition of the foundation, existing grout and concrete.

- Mobilization: Bringing necessary materials, tools, and manpower to the site.

- Preparation: Removing obstructions like piping, wiring, and structures for operations.

- Reference Setup: Establishing valid references for motor skid position and check initial alignments.

- Foundation Work: Loosening foundation bolts, remove existing grout around the skid.

- Gearbox Support: Using Alphapads® or hydraulic jacks for supporting and preparing the foundation for chipping.

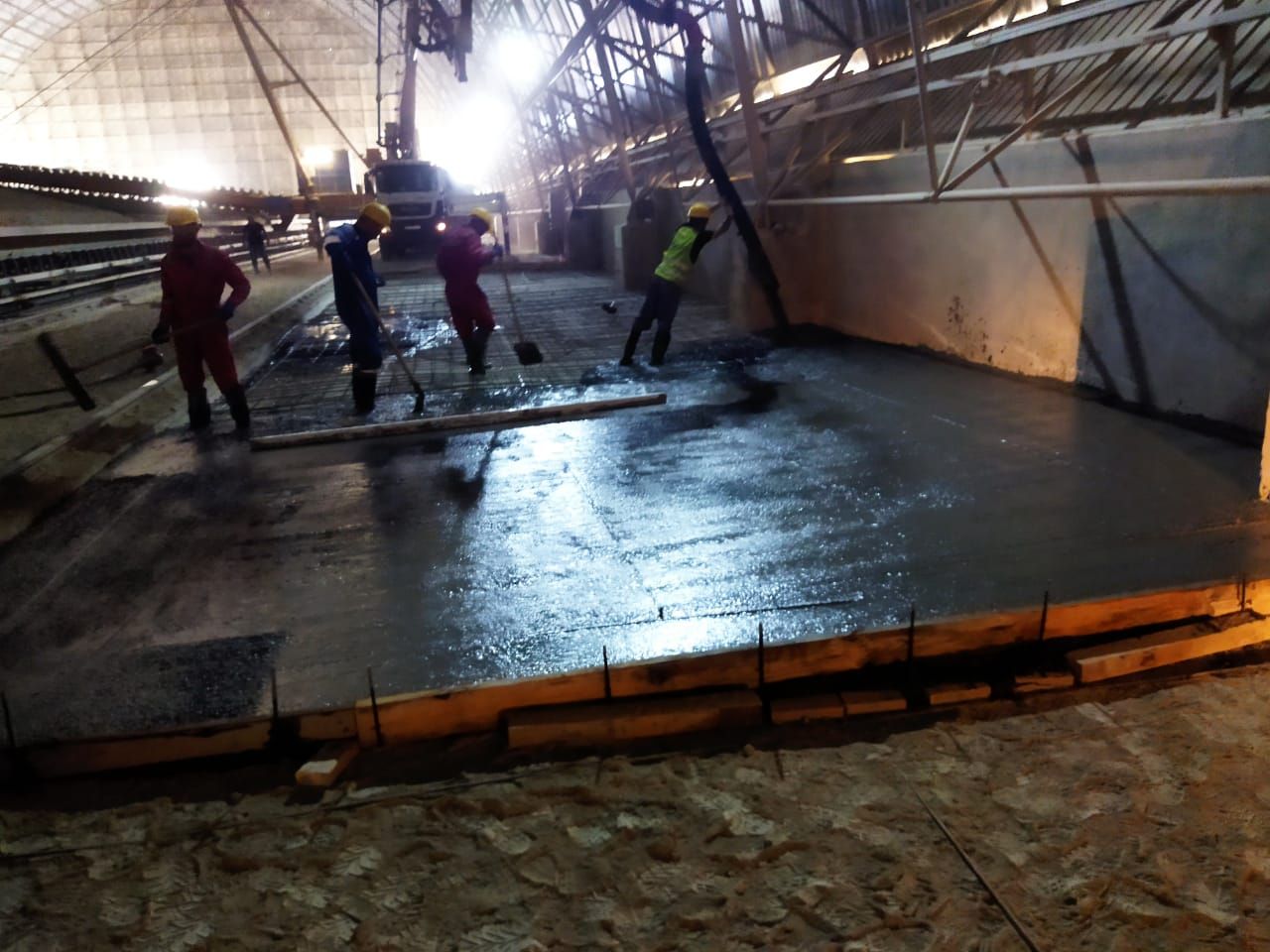

- Surface Preparation: Chipping at the skid/motor foundation to reach sound concrete/grout.

- Formwork Installation: Installing formwork and seal with epoxy putty.

- Motor Skid Installation: Installing motor skid frame, possibly with motor.

- Alignment Check: Ensure that proper alignment of gearbox to mill.

- Epoxy Grout Preparation: Mixing the substances with aggregates to prepare the epoxy grout

- Epoxy Grout Pouring: Applying ALPHATEC® 800 to cover soleplate.

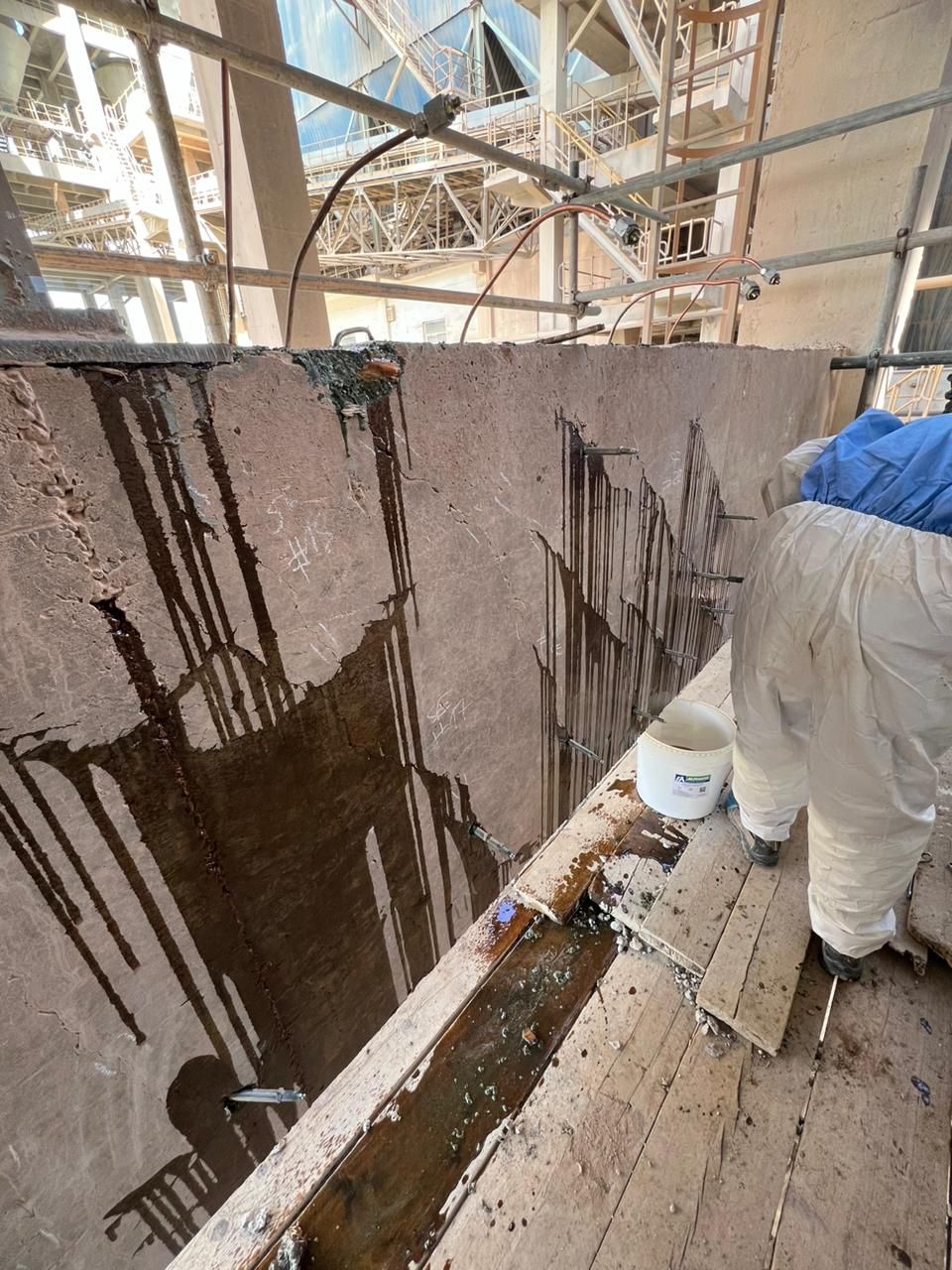

- Pre-injection Activities: V crack opening and sealing the external cracks after installation of packers

- Injection Hole Drilling: Drilling holes for epoxy injection.

- Injection Hole Preparation: Cleaning, drying, and preparing holes with reinforcing materials.

- Epoxy Resin Injection: Injecting ALPHATEC® 342 to fill voids.

- Demobilization

- Final documentation and project delivery

Project: Restoring Grout on CMD Gearbox, Auxiliary & GE Induction Motor

Client: NORM Cement Plant

Location: Garadagh district, Umid settlement, Salyan highway, Sangargaya

Scope of Work:

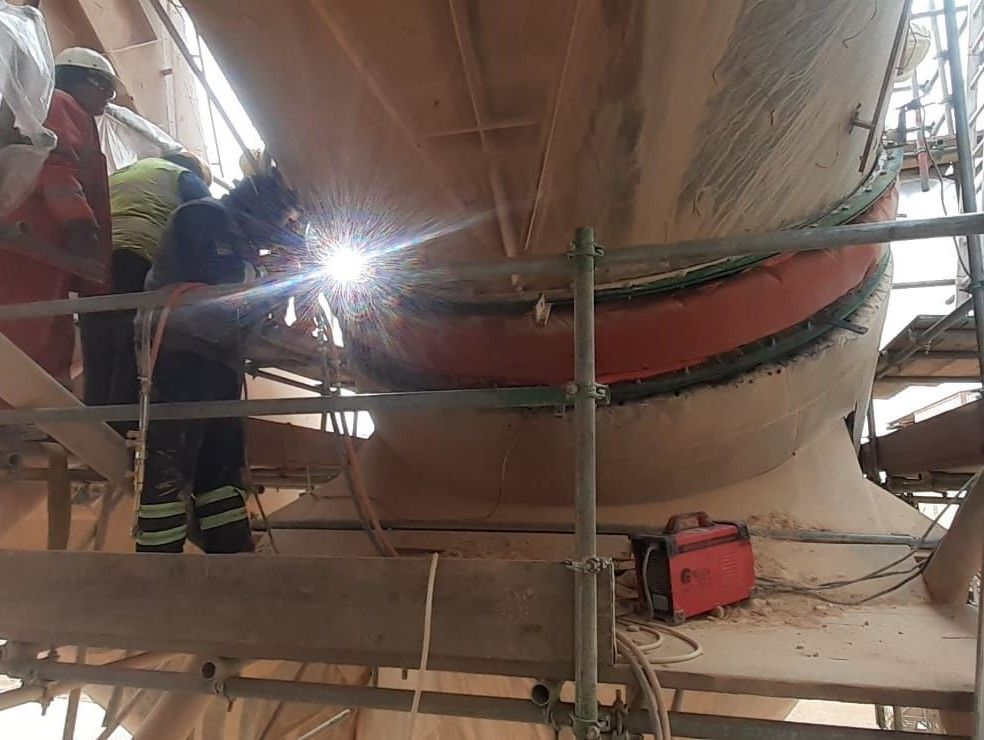

Fabrication and installation of the sliding roof above the main bag filter and the upper filter chamber

Fabrication and installation of the sliding roof above the main bag filter and the upper filter chamber Epoxy grout and epoxy injection works on CMD Gearbox, Auxiliary and GE Induction Motor and ID fan foundation

Epoxy grout and epoxy injection works on CMD Gearbox, Auxiliary and GE Induction Motor and ID fan foundation Renewal of the Air Pipes and Metal Structure of the Aeronov Filters for Clinker Material Transitions at the HOLCIM Cement Plant

Renewal of the Air Pipes and Metal Structure of the Aeronov Filters for Clinker Material Transitions at the HOLCIM Cement Plant - Projects